High-Yield Entomology: The Engine of Protein and Waste Conversion

The Ecoladang Insect Farming unit, primarily utilizing Black Soldier Fly (BSF) larvae, is central to our circular economy model. This system transforms low-value agricultural waste, including industrial byproducts like Palm Oil Mill Effluent (POME), into high-value protein meal and specialized food additives.

By converting environmental liabilities into profitable inputs, this unit provides a stable revenue stream and dramatically lowers the operational costs of our other Micro Farms (e.g., Aquaculture). Our approach is built on efficient, scalable, and fully integrated Standard Operating Procedures (SOPs), positioning us at the forefront of the rapidly growing insect protein market.

By converting environmental liabilities into profitable inputs, this unit provides a stable revenue stream and dramatically lowers the operational costs of our other Micro Farms (e.g., Aquaculture). Our approach is built on efficient, scalable, and fully integrated Standard Operating Procedures (SOPs), positioning us at the forefront of the rapidly growing insect protein market.

1. The Zero-Cost Feedstock Loop

The unparalleled profitability of our Insect Farms stems from eliminating high-cost traditional feed. We instead utilize high-volume, readily available waste streams from the local environment and our integrated ecosystem.

Guaranteed Input Security

- Palm Oil Mill Effluent (POME): BSF larvae are renowned for efficiently converting this high-volume industrial waste into valuable biomass, addressing a major environmental liability for large plantations and creating a near-zero-cost feed source.

- Mycelium Waste:Spent substrate from our Mycelium & Mushroom Cultivation unit becomes a primary, highly nutritious base for the insect colonies, ensuring a consistent and captive supply of feed.

- Discarded Produce: "Cosmetically filtered food" and unsaleable produce are safely processed and utilized as insect feed, providing essential "eco-cleaning" services.

- Grains and Husks:Low-value agricultural byproducts are used as cost-effective, high-bulk food sources to manage colony density.

This guaranteed, low-cost input supply shields the farm from fluctuating global commodity prices, ensuring stable margins.

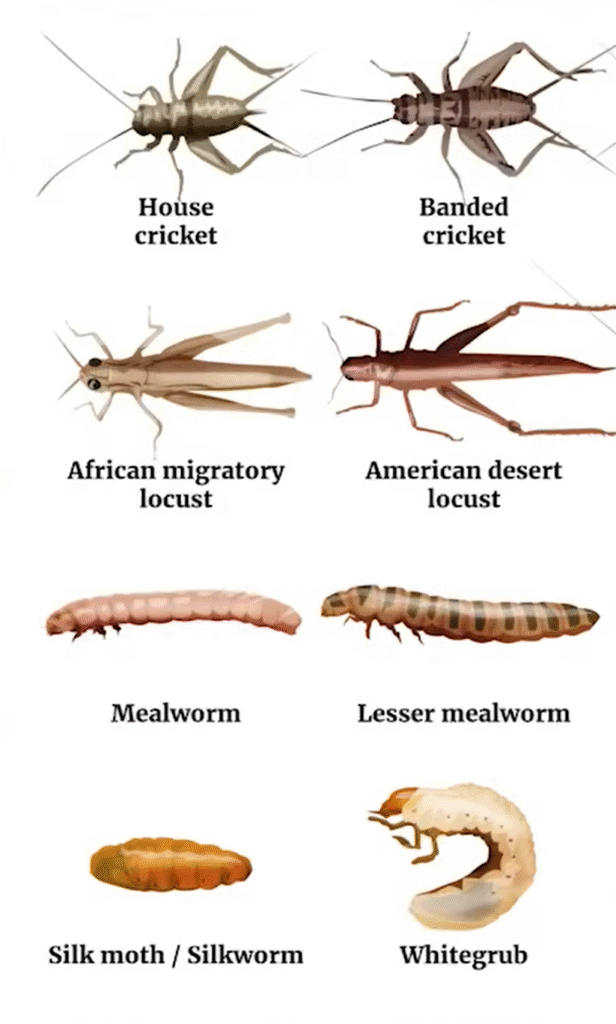

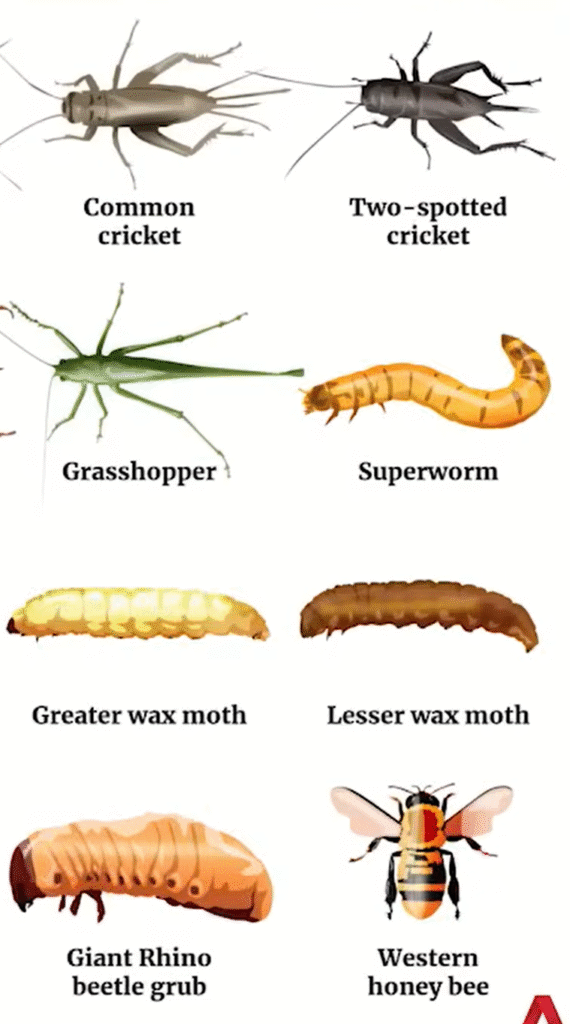

Insect Farming is highly versatile, providing products for multiple recession-proof global markets. We focus on species like BSF and Superworms to ensure rapid production and short time-to-market.

BSF larvae are dried and finely ground into a high-protein meal or powder, replacing expensive soy and fishmeal. - Livestock, Poultry, and Aquaculture Feeds (the largest volume market).

The waste byproduct of BSF larvae is a superior, nutrient-rich soil amendment. - Gardening, organic farming, and land restoration; sold as a natural, value-added fertilizer.

We implement specialized gut-loading protocols to enhance nutritional profiles based on customer requirements. - Premium, high-margin specialized pet and exotic animal feed markets.

While requiring a separate, sterile, and HACCP-compliant facility, our SOPs provide the blueprint for future expansion into the human food market. Crickets and specialized BSF products are the initial focus, offering high-protein powders for snacks, protein bars, and powders.

The Ecoladang franchise provides the complete blueprint for the Insect Farming unit, ensuring rapid deployment and stable, high-yield operation regardless of prior experience.

Operational Support

- Climate Control & SOPs: Detailed Standard Operating Procedures (SOPs) cover critical factors for BSF and other species, including pest control, climate optimization, and colony health to maximize yield and output consistency.

- Demand-Driven Production: The PCDS (Pillar 2) integrates with inventory and sales data to optimize breeding cycles. This ensures resources are deployed only when market demand is confirmed, minimizing product shelf-life risk.

- Vertical Facility Design: Our designs maximize density using vertical space efficiently, allowing for rapid expansion that is not limited by arable land.

Strategic Investment Stability

- High ROI on Waste: We monetize waste that plantation owners typically pay to dispose of (POME, biomass), transforming environmental liability into a verifiable, measurable profit center.

- Instant Market Credibility:By adopting our certified SOPs, the farm is instantly positioned for the premium feed market, including specialized gut-loaded products, ensuring quality and price points above generic competitors.

- Integrated Agility:The unit's stability, low operating costs, and high margins make it a powerful, resilient, and profitable component of the overall ecosystem.

Core Infrastructure

The entire gasification unit is integrated with the PCDS (Pillar 2) where the AI models and software services optimize feedstock rates, gas quality, and power output in real-time. This digital integration maximizes fuel conversion efficiency and ensures stable 400V power delivery precisely when and where it is needed.

The next stage in this pillar, Biomass Carbonization, takes the solid output from this process and turns it into our first high-value commercial and agricultural product. Do you want to review and expand that page next?